Thursday, 5 March 2026

KPM Analytics unveils AI-powered inspection system for meat and poultry

Second-generation TheiaVu WD-300 system offers precision, reliability, and speed – up to 10x faster than manual product checks Meat and poultry processors face ongoing challenges with quality control, consistency, and…

Second-generation TheiaVu WD-300 system offers precision, reliability, and speed – up to 10x faster than manual product checks

Meat and poultry processors face ongoing challenges with quality control, consistency, and labour shortages. Traditional manual inspection methods are time-consuming, subjective, and provide limited data. KPM Analytics introduces TheiaVu WD-300, the first AI-enabled at-line vision inspection system designed specifically for meat and poultry applications.

The new AI-powered TheiaVu WD-300 includes advanced features and capabilities from previous system generations to answer specific demands from users in the meat and poultry industry. It eliminates the need for callipers and colour charts to save labour and avoid subjective assessment. The at-line visual inspection reduces all these manual measurements into a single pass through a conveyor for greater precision, reliability, and speed compared to other visual inspection methods.

The TheiaVu WD-300 is optimised for a wide range of meat and poultry products, including chicken portions, beef cuts, processed meats and other further breaded products such as chicken nuggets and sandwich patties.

Each TheiaVu WD-300 is equipped with measuraAITM, available in measure 4 software, which provides a simple interface that allows users to take advantage of recent developments in artificial intelligence and train their own AI models based on provided templates for their unique products. The Measure 4 software is also available in all TheiaVu models, including the TV-250 product line for the baking industry.

Technology

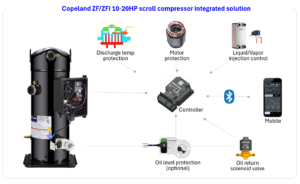

Copeland Launches ZF/ZFI 10-20HP Scroll Compressors

Mar 05, 2026 | Company News

WA Scientists Discover New Deep-Sea Crustacean Stocks with Strong Commercial Potential

Mar 05, 2026 | Australia

Food Testing

NSF and Circle H Collaborate to Enable Global Certification Access

Mar 04, 2026 | Company News

Australian Medical Bodies Push for Compulsory Health Star Labelling

Feb 24, 2026 | Australia

Tim Hortons Singapore Secures Majlis Ugama Islam Singapura Halal Certification Ahead of Ramadan

Feb 23, 2026 | Company News

More Popular

Copeland Launches ZF/ZFI 10-20HP Scroll Compressors

Mar 05, 2026 | Company News

Singapore Expands Support for Local Farms to Strengthen Food Security

Mar 05, 2026 | Food Security