Tuesday, 17 February 2026

Vietnam’s Siegwerk’s Commitment to safest inks and coatings

Siegwerk not only offers toluene-free packaging inks but also helps printers to switch to these safer solutions and thus meet the increasing requirements of brand owners banning the usage of…

Siegwerk not only offers toluene-free packaging inks but also helps printers to switch to these safer solutions and thus meet the increasing requirements of brand owners banning the usage of Toluene in ink formulations intended for food packaging material

Packaging plays an important role in protecting food from contamination. Printing inks are an integral part of the packaging and are important because they provide visual information and brand awareness, and are decorative of the packaging. Packaging safety remains a highly important topic as no food is safe without proper packaging.

As a global printing inks and coatings manufacturer, Siegwerk is making every effort to develop the safest inks and coatings for food packaging worldwide. To date, Siegwerk has established itself as a global leader in safe packaging solutions and has already helped numerous brand owners with its expertise in terms of food safety and systematic processes to ensure regulatory compliance and avoid food contamination risks.

Siegwerk not only offers toluene-free packaging inks but also helps printers to switch to these safer solutions and thus meet the increasing requirements of brand owners banning the usage of Toluene in ink formulations intended for food packaging material. Toluene is a well-known solvent that has been classified as suspected of damaging the unborn child. Furthermore, when printing with toluene-based inks, there is an immanent risk of residual toluene in packaging being transferred to the packed food and beverages which impacts the organoleptic properties of the product thus leading to food quality and safety as well as legal compliance issues.

Towards the end of 2023, the Ministry of Science and Technology of Vietnam announced and issued the National Standard “Printing ink for food packaging – General requirements”. Toluene is now a prohibited substance in ink formulation according to the Vietnam-TCVN 13928:2023. Some printers/converters have already switched to safe options.

Technology

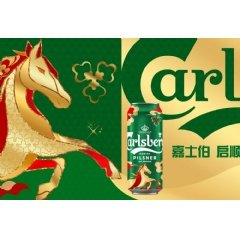

Carlsberg Launches AI-Crafted Lunar New Year Packaging

Feb 17, 2026 | Beverages

FAO Experts Assess Risk of Antimicrobial Resistance Spreading via Food Loss and Waste

Feb 17, 2026 | Sustainability

Setting the Standard for Sustainable Ingredients

Feb 16, 2026 | Ingredients

Food Testing

Redefining Trust in Organic Foods through Independent Testing

Feb 13, 2026 | Food Safety and Testing

AFNOR International Eyes Global Food Safety Growth with HACCP Group Takeover

Feb 04, 2026 | Australia

More Popular

Cerealto Sells Pasta Unit to Specialist Player Cerealis

Feb 17, 2026 | Company News

New Nestlé Vital nutritional drink targets rising demand for healthy-ageing solutions

Feb 17, 2026 | Company News

Carlsberg Launches AI-Crafted Lunar New Year Packaging

Feb 17, 2026 | Beverages