Friday, 27 February 2026

Singapore develops low-temperature technique to 3D print milk products

Traditionally, 3D-printed foods have often used SLS & hot-melt extrusion methods In a recent research done by the Singapore University of Technology and Design (SUTD), it is found that milk-based…

Traditionally, 3D-printed foods have often used SLS & hot-melt extrusion methods

In a recent research done by the Singapore University of Technology and Design (SUTD), it is found that milk-based products can now be 3D-printed at room temperature without additives, hence preserving its temperature-sensitive nutrients while appealing to consumers on the hunt for clean labels.

Researchers from SUTD have developed the direct ink writing (DIW) technique, which is now subject to ‘ongoing plans for commercialization’.

Lead author and SUTD Ph.D. candidate, Lee Cheng Pau, stated in the research that the ‘novel yet simple’ method can be used in formulating various nutritious foods, including those served to patients in hospitals for their special dietary needs.

A variety of shapes were successfully printed, including a couch, a cloverleaf, a fortress and a wheel. The only ingredients are milk powder and water, which is added to control the rheology. The texture depends on the final shape and size. Meanwhile, the taste is simply that of powdered milk. Further, printing time depends on the complexity of the shape and size.

Traditionally, 3D-printed foods have often used selective laser sintering (SLS) and hot-melt extrusion methods. However, these methods are not always compatible with temperature-sensitive nutrients found in certain foods.

To tackle these limitations, the SUTD team changed the rheological properties of the printing ink. The printable ink needed to exhibit shear-thinning behavior, where the viscosity is low at a high shear rate to allow extrusion of ink from the nozzle.

Extensive characterizations of the formulated milk ink were also conducted to analyze their rheological properties and ensure optimal printability.

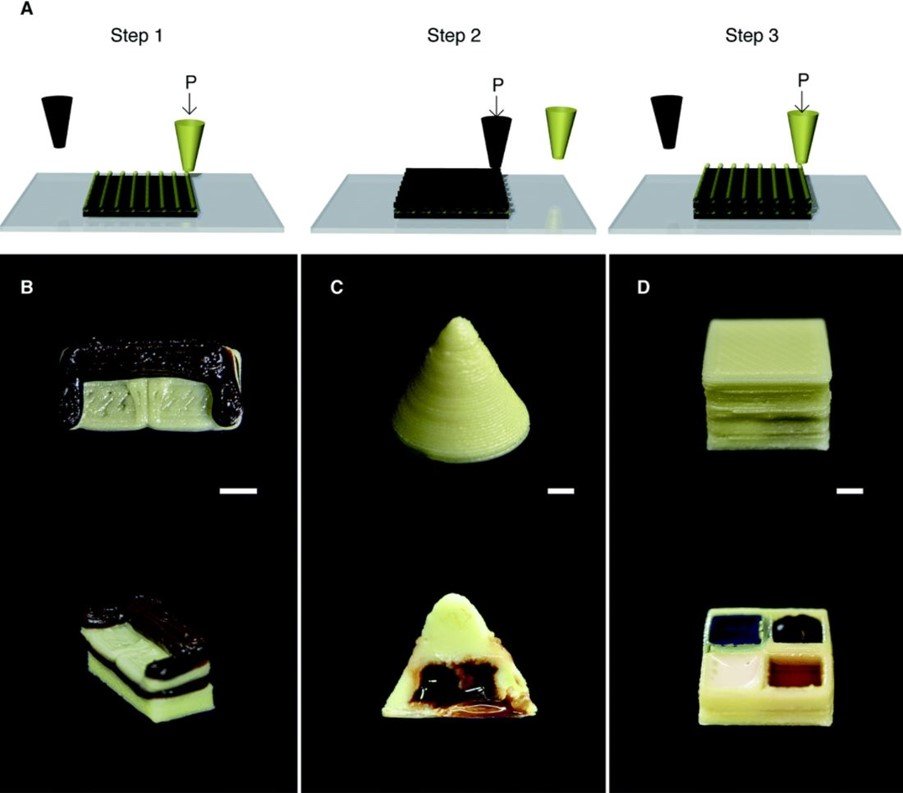

(Image caption- Researchers investigated printing the milk alongside other foods)

Technology

Ingredion Thailand Achieves 100% Sustainably Sourced Cassava

Feb 27, 2026 | Company News

Deakin University and Bellarine Foods Partner to Develop Sustainable Marine-Derived Proteins

Feb 26, 2026 | Australia

Royal Unveils Refreshed Jute Bag Design for 20lb Authentic Basmati

Feb 25, 2026 | Company News

Food Testing

Australian Medical Bodies Push for Compulsory Health Star Labelling

Feb 24, 2026 | Australia

Tim Hortons Singapore Secures Majlis Ugama Islam Singapura Halal Certification Ahead of Ramadan

Feb 23, 2026 | Company News

More Popular

Fagron Acquires Pharmavit Europe for €68Mn to Expand Nutraceutical Portfolio

Feb 27, 2026 | Company News

Arla Foods Invests EUR 300Mn in New Cheese Dairy in Sweden

Feb 27, 2026 | Company News

Beyond Meat Broadens Portfolio Beyond Protein with Sparkling Plant-Based Drink Line

Feb 27, 2026 | Beverages