Monday, 16 February 2026

JJ-Lurgi commissions its largest oilseed crushing plant

The project is JJ-Lurgi’s largest oilseed crushing and solvent extraction plant to-date, designed to process soybean and rapeseeds with the Twin-Track Sliding Cell (SC) Extractor Malaysia based JJ-Lurgi, the life…

The project is JJ-Lurgi’s largest oilseed crushing and solvent extraction plant to-date, designed to process soybean and rapeseeds with the Twin-Track Sliding Cell (SC) Extractor

Malaysia based JJ-Lurgi, the life sciences joint venture of diversified industrial conglomerate, Jebsen & Jessen Group, has successfully commissioned its largest oilseed crushing and solvent extraction plant for Sinograin Oils & Fats Industrial Dongguan Co. Ltd. Continuing its efforts to meet the growing demand and market needs for oilseed extraction and refining technology, the latest project adds to its portfolio of more than 300 completed process plants across South East Asia and China.

JJ-Lurgi, Jebsen & Jessen Group’s joint venture with Air Liquide, is a full-fledged engineering practice and leading innovator in the field of oils & fats, oleochemicals, and biodiesel. Sinograin Oils & Fats Industrial Dongguan Co. Ltd., based in China, manufactures and distributes agricultural products.

Soybean oil is the second most popular edible oil today, accounting for 28% of edible vegetable oil consumed worldwide. Growing demand for soybean and its end products, largely driven by soybean oil and soybean meal, outpaces the growth in global supply for the commodity. With fierce competition for the commodity, optimising oil extraction for soybeans and improving energy efficiency is crucial for manufacturers to gain a competitive advantage.

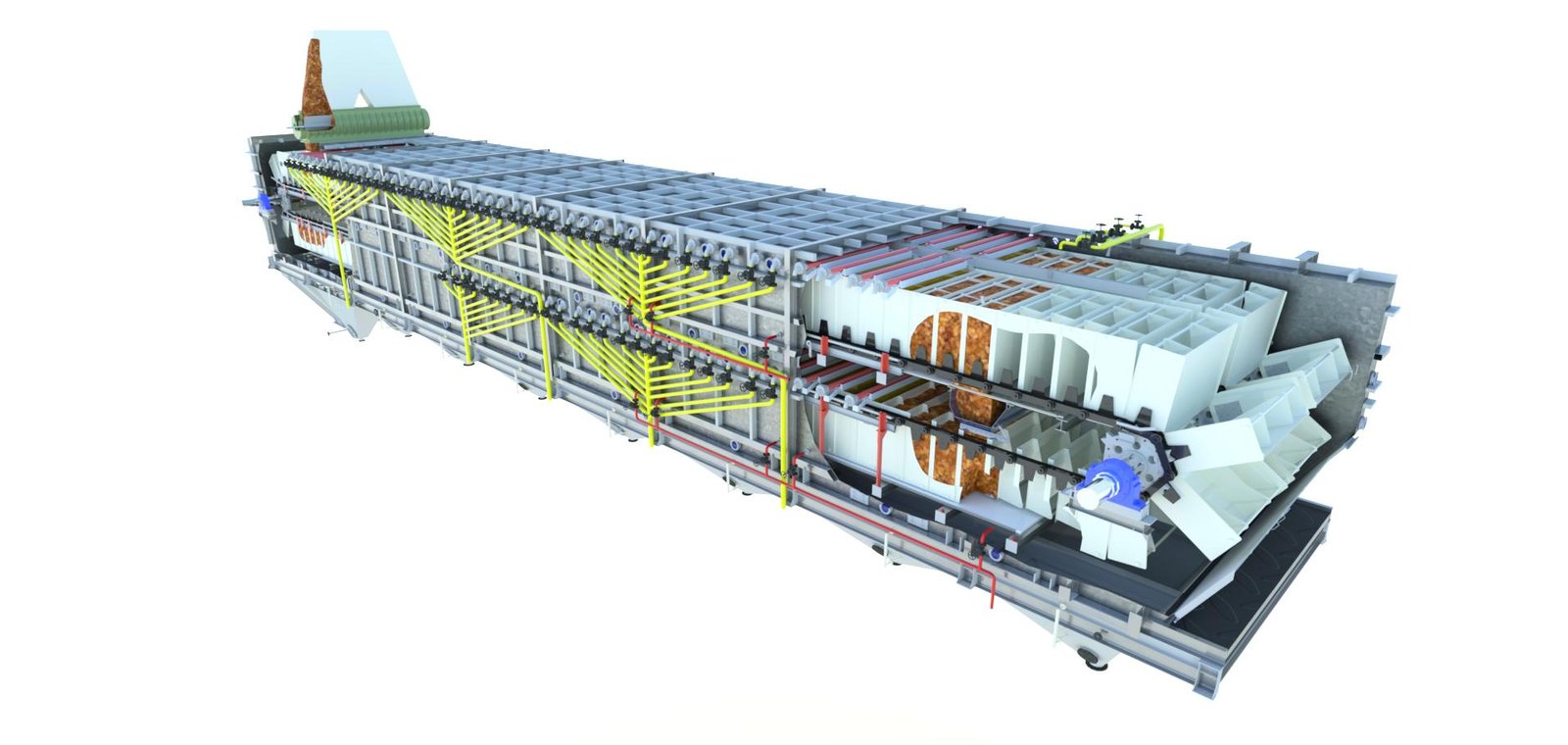

The team at JJ-Lurgi was able to complete the commissioning work for Sinograin Oils & Fats Industrial Dongguan Co. Ltd. in just under a month despite the COVID-19 pandemic, overcoming challenges and restrictions that arose. The project is JJ-Lurgi’s largest oilseed crushing and solvent extraction plant to-date, designed to process soybean and rapeseeds with the Twin-Track Sliding Cell (SC) Extractor. This included a successful test run with all contractual agreements and expectations met; the plant has since produced more than 100,000 tonnes of soybean and achieved target utilities consumption figures.

“Throughout the pandemic, we took steps to ensure business continuity while safeguarding the health of our employees. Our vast local network in China and South East Asia has allowed us to adapt and respond to the rapidly changing situation quickly. We were able to tap on our local team to complete the project according to schedule and also ensure that all requirements and targets were well met,” said Jakob Helms, Managing Director of JJ-Lurgi.

The Twin-Track Sliding Cell (SC) Extractor, the first of its kind available globally, is multi-seed capable – allowing it to process different seeds such as soybean, rapeseed, palm kernel, and sunflower seeds. It is capable of capacities above 5000 tonnes per day, maximises oil extraction, and grants improved energy efficiency; with a unique mild vacuum technology that lowers the hexane content in wet meals and reduces the live steam consumption at the DTDC (desolventising, toasting, drying, and cooling) stage. This new technology, debuted in Sinograin’s extraction plant, has achieved a 20% and 30% reduction in the consumption of steam and hexane respectively, as compared to plants of similar scope.

“With over 20 years of experience in the industry, we have built deep technological and engineering expertise that has led to cutting-edge innovations. The Twin-Track SC Extractor is a result of years of improvements and innovations to our SC Extractor. We are proud to be able to complete the new plant for Sinograin, and our success adds to the accolades we’ve received in our work with our customers,” added Jakob Helms, Managing Director of JJ-Lurgi.

The Twin-Track SC Extractor is based on the third-generation model of JJ-Lurgi’s SC Extractor, first conceived in the early 1940s, and is also available as a Single-Track SC Extractor.

Technology

Setting the Standard for Sustainable Ingredients

Feb 16, 2026 | Ingredients

Chiquita Advances Banana Innovation with Completion of Yelloway Banana Pan-Genome

Feb 13, 2026 | Company News

Food Testing

Redefining Trust in Organic Foods through Independent Testing

Feb 13, 2026 | Food Safety and Testing

AFNOR International Eyes Global Food Safety Growth with HACCP Group Takeover

Feb 04, 2026 | Australia

More Popular

JBS Inaugurates New Plant in Saudi Arabia

Feb 16, 2026 | Company News

Milano Cortina 2026 Licensed Candies Released Globally

Feb 16, 2026 | Company News

Vinarchy appoints Nicole Battistessa as MD Australia and New Zealand

Feb 16, 2026 | Australia