Friday, 6 March 2026

Maestrani boosts chocolate mass production efficiency with Bühler

Maestrani has achieved an 18 per cent increase in production efficiency Swiss chocolate producer Maestrani Schweizer Schokoladen AG and Swiss technology group Bühler are taking their long-standing partnership to the…

Maestrani has achieved an 18 per cent increase in production efficiency

Swiss chocolate producer Maestrani Schweizer Schokoladen AG and Swiss technology group Bühler are taking their long-standing partnership to the next level through digitalisation. With the support of Bühler’s advanced digital solutions, Maestrani has achieved an 18 per cent increase in production efficiency, while gaining transparency and laying the foundation for a smart factory.

With a heritage spanning more than 170 years, Maestrani produces over 4,500 tonnes of chocolate annually for its iconic brands Minor, Munz, and Maestrani. At its Flawil site, the company also welcomes over 230,000 visitors each year to its immersive Chocolarium World of Discovery.

Guided by its purpose of “making the world sustainably happier, bit by bit,” Maestrani is committed to continuous improvement and innovation. “To meet growing consumer expectations and ensure our long-term competitiveness, we must be faster, more adaptable, and ready for future challenges. Digitalisation plays a key role in achieving this,” says Christoph Birchler, CEO of Maestrani.

In 2016, Maestrani initiated its digital transformation journey in collaboration with Bühler, aiming to enhance process transparency and efficiency. Central to this effort is Bühler Insights, Bühler’s digital platform that connects machines, aggregates data, and visualises operational performance.

By installing intelligent sensors across critical equipment, Maestrani began capturing real-time data from various production steps, including mixing, refining and conching. Bühler Insights consolidates this information, enabling operators and managers to monitor key performance indicators (KPIs), identify inefficiencies, and make data-based decisions.

“With Bühler Insights, we now collect and analyse dozens of data points per machine. This level of transparency allows us to move from reactive to proactive process management,” says Patrik Keller, Head of Production & Logistics at Maestrani.

Technology

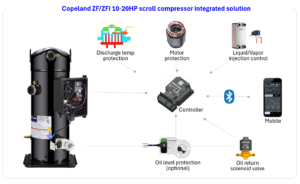

Copeland Launches ZF/ZFI 10-20HP Scroll Compressors

Mar 05, 2026 | Company News

WA Scientists Discover New Deep-Sea Crustacean Stocks with Strong Commercial Potential

Mar 05, 2026 | Australia

Food Testing

NSF and Circle H Collaborate to Enable Global Certification Access

Mar 04, 2026 | Company News

Australian Medical Bodies Push for Compulsory Health Star Labelling

Feb 24, 2026 | Australia

Tim Hortons Singapore Secures Majlis Ugama Islam Singapura Halal Certification Ahead of Ramadan

Feb 23, 2026 | Company News

More Popular

Women, Midlife and the Quest for Healthy Longevity

Mar 06, 2026 | Feature

Copeland Launches ZF/ZFI 10-20HP Scroll Compressors

Mar 05, 2026 | Company News