Friday, 6 March 2026

Powering Indian foods onto global plates: Amar Pure Gold’s export strategy

Amit Goyal, CEO & Director, Amar Pure Gold As India’s food processing sector scales up to meet rising global demand for ready-to-eat and frozen ethnic foods, companies like Amar Pure…

Amit Goyal, CEO & Director, Amar Pure Gold

As India’s food processing sector scales up to meet rising global demand for ready-to-eat and frozen ethnic foods, companies like Amar Pure Gold are playing a pivotal role in building export-ready manufacturing ecosystems. With a large agro-food park planned in Una, Himachal Pradesh, and investments exceeding Rs 400 crore, Amar Pure Gold is deepening its manufacturing footprint while strengthening farm linkages and global market access. In this conversation with NUFFOODS Spectrum, Amit Goyal, CEO & Director, Amar Pure Gold, discusses the strategic rationale behind the project, evolving policy support, technology adoption, and the company’s vision for India as a global food manufacturing hub.

What strategic factors led Amar Pure Gold to choose Himachal Pradesh for its next large-scale agro-food park, and how does this location fit into your long-term manufacturing and export strategy?

Himachal Pradesh has always been a key part of Amar Pure Gold’s long-term expansion strategy. We are currently developing a 25-acre state-of-the-art manufacturing facility in the state, and the proposed large-scale agro-food park further strengthens our presence and commitment to the region. The foothills of Himalya’s with natural resources align well with our focus on purity, quality, and global food standards. Additionally, Amar Pure Gold’s policies align with what Himachal Pradesh has to offer: strong connectivity, proximity to raw-material belts, a skilled workforce, and a supportive government ecosystem. Together, these factors make it an ideal location to scale manufacturing, strengthen our export capabilities, and build a globally competitive food processing hub. This agro-food park is not just an expansion of capacity; it is Amar Pure Gold’s commitment to a long-term strategic investment aimed at strengthening Amar Pure Gold’s manufacturing backbone, enhancing export competitiveness, and building a globally benchmarked food processing ecosystem from India for the world.

Can you share more details about the planned product categories, processing capabilities, and target export markets for the upcoming agro-food park in the Una district?

The upcoming agro-food park in Una is envisioned as a large-scale, export-led manufacturing ecosystem designed to take Indian food products to the global stage. The facility will house advanced processing lines for ready-to-eat foods, frozen Indian sweets, and frozen snacks, supported by modern freezing, packaging, and quality-control infrastructure built to international benchmarks. Amar Pure Gold currently exports to over 10 countries, with a strong footprint in key global markets such as the UK, USA, Canada, and Australia. With this new agro-food park, we aim to significantly scale volumes while strengthening our presence in the UAE and major Asian markets and expanding into new geographies. This project represents a strategic leap towards building a globally integrated supply chain and reinforcing India’s position as a trusted source of high-quality processed foods.

How will this new facility strengthen Amar Pure Gold’s farm-to-fork integration, particularly regarding sourcing from local farmers and building resilient agricultural supply chains?

The new agro-food park in Una will further strengthen Amar Pure Gold’s farm-to-fork integration. We already have a farmer-centric, transparent, and resilient agricultural sourcing ecosystem. Our model is designed to minimise intermediaries and create direct linkages with farmers through contract farming and forward agreements, ensuring assured offtake, predictable demand, and clearly defined quality benchmarks. We have rooted integrations with local Farmer Producer Organizations (FPOs) and Farmer Producer Companies (FPCs) as aggregation and logistics hubs. This enables collective grading, storage, primary processing, and efficient transport to the plant, reducing wastage and logistics costs. The sourcing catchment is structured into zonal clusters, supported by buffer stocks and supplemental procurement during lean seasons. We further wish to invest in farmer upliftment through training, certified inputs, digital platforms for crop monitoring and payments, and incentive-based pricing. Together, these measures will create a resilient, scalable, and inclusive supply chain benefiting both farmers and global consumers.

With cumulative investments now exceeding ₹400 crore, how do you see India’s food processing ecosystem evolving in terms of infrastructure readiness, policy support, and export competitiveness?

With cumulative investments exceeding ₹400 crore, Amar Pure Gold’s journey mirrors the rapid evolution of India’s food processing ecosystem. Our investments across large-scale manufacturing, integrated food parks, cold-chain infrastructure, and export-ready facilities reflect the growing readiness of India to support globally competitive food processing operations. We are also coming up with projects with the mainstream players in the UK and Australia, further pushing our boundaries globally. India’s policy environment has matured significantly, with strong government support, infrastructure-led growth, and a progressive trade framework. At the same time, global demand for Indian cuisine continues to rise across ready-to-eat, frozen, and ethnic food categories. Leveraging this demand, along with India’s expanding Free Trade Agreements, Amar Pure Gold is well-positioned to strengthen its export leadership and contribute meaningfully to India’s emergence as a global food manufacturing and export hub.

What role will technology, automation, and quality systems play in ensuring global compliance and consistency across your expanding manufacturing footprint?

Technology and quality systems form the backbone of Amar Pure Gold’s expanding manufacturing footprint. Across our facilities, we are integrating advanced IoT-SCADA–enabled systems to ensure real-time monitoring of production parameters, traceability, energy efficiency, and process consistency. This allows us to maintain tight control over quality, yields, and operational efficiency at scale. Automation across processing, freezing, and packaging lines helps us deliver uniform products that meet stringent global standards. Complementing this is a strong focus on quality compliance and in-house R&D, enabling continuous product improvement, regulatory alignment, and customisation for international markets. Together, technology, automation, and robust quality frameworks ensure reliability, compliance, and consistency across all our manufacturing locations worldwide.

Employment generation is a key outcome of this project. How does Amar Pure Gold plan to build local capabilities and skill development to support sustainable growth in the region?

Employment generation and local capability building are central to Amar Pure Gold’s growth philosophy. The upcoming agro-food park has already started creating large-scale direct and indirect employment across manufacturing, quality, logistics, and allied services, with a strong focus on hiring and training local talent. As a part of human resource management and upliftment, we do invest in structured skill-development programs in collaboration with government agencies, technical institutes, and agri-extension bodies to build a future-ready workforce. Equally important is skill integration at the farm level. Through training, technology adoption, and quality-linked incentives, we work closely with farmers to enhance productivity, post-harvest handling, and supply reliability. This integrated approach ensures sustainable livelihoods, stronger agricultural supply chains, and inclusive growth for the region while supporting Amar Pure Gold’s long-term expansion.

Shraddha Warde

shraddha.warde@mmactiv.com

Technology

Sidel introduces SWING Evo Pasteuriser, Redefines Efficiency through Intelligent Design

Mar 06, 2026 | Company News

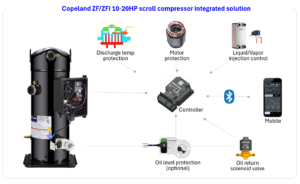

Copeland Launches ZF/ZFI 10-20HP Scroll Compressors

Mar 05, 2026 | Company News

Food Testing

NSF and Circle H Collaborate to Enable Global Certification Access

Mar 04, 2026 | Company News

Australian Medical Bodies Push for Compulsory Health Star Labelling

Feb 24, 2026 | Australia

Tim Hortons Singapore Secures Majlis Ugama Islam Singapura Halal Certification Ahead of Ramadan

Feb 23, 2026 | Company News

More Popular

Nutrition Education Drives Adoption of Seaweed and Mussels among Bangladesh Coastal Communities

Mar 06, 2026 | Food Security

Sidel introduces SWING Evo Pasteuriser, Redefines Efficiency through Intelligent Design

Mar 06, 2026 | Company News