Saturday, 7 March 2026

VEMAG breaks ground on new production hall

The new facility will be dedicated to manufacturing double screws and infeed scrolls for vacuum-filling machines Germany-based VEMAG is taking a significant step forward in its growth strategy with the…

The new facility will be dedicated to manufacturing double screws and infeed scrolls for vacuum-filling machines

Germany-based VEMAG is taking a significant step forward in its growth strategy with the groundbreaking of a new 4,600-square-meter production hall. This substantial investment strengthens the company’s commitment to innovation and operational efficiency, further cementing its success in the industry.

The new facility will be dedicated to manufacturing double screws and infeed scrolls for vacuum-filling machines. These double screws, a crucial component of vacuum filling machines, employ a double-spindle principle to gently transport flowable products. The innovative feeding system consists of only two parts—the double screw and its housing—allowing for quick changeovers that can be performed directly by operators. This streamlined design not only enhances efficiency but also reduces downtime by simplifying intermediate cleaning processes.

The groundbreaking ceremony was attended by VEMAG’s management, the local mayor, and members of the press. In his address, CEO Andreas Bruns highlighted the significance of the investment: “This expansion reaffirms our commitment to customer-centric innovation. By increasing our production capacity, we aim to drive advancements in weight accuracy, gentle product handling, and the longevity of our double screws.”

Production Manager Jonas Hohls emphasised the operational benefits of the new facility: “The entire production process will be housed in this new hall, from base material storage to advanced manufacturing solutions and packaging. This will minimise distances within production and optimise efficiency.”

Scheduled for completion in 2026, the state-of-the-art facility represents an investment of approximately 7.5 million euros. Additional funding is also being allocated for cutting-edge machinery and equipment, reinforcing VEMAG’s efforts to enhance production efficiency and maintain its competitive edge in the market.

Technology

Sidel introduces SWING Evo Pasteuriser, Redefines Efficiency through Intelligent Design

Mar 06, 2026 | Company News

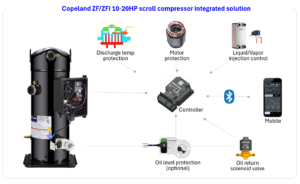

Copeland Launches ZF/ZFI 10-20HP Scroll Compressors

Mar 05, 2026 | Company News

Food Testing

NSF and Circle H Collaborate to Enable Global Certification Access

Mar 04, 2026 | Company News

Australian Medical Bodies Push for Compulsory Health Star Labelling

Feb 24, 2026 | Australia

Tim Hortons Singapore Secures Majlis Ugama Islam Singapura Halal Certification Ahead of Ramadan

Feb 23, 2026 | Company News

More Popular

Nutrition Education Drives Adoption of Seaweed and Mussels among Bangladesh Coastal Communities

Mar 06, 2026 | Food Security

Sidel introduces SWING Evo Pasteuriser, Redefines Efficiency through Intelligent Design

Mar 06, 2026 | Company News