Friday, 6 March 2026

Bringing PFAS testing to the point of need

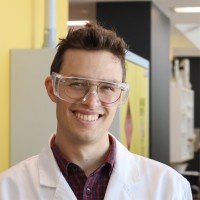

Henry Bellette, PhD candidate at La Trobe University Per- and polyfluoroalkyl substances (PFAS) continue to raise global concern due to their persistence in the environment and growing links to human…

Henry Bellette, PhD candidate at La Trobe University

Per- and polyfluoroalkyl substances (PFAS) continue to raise global concern due to their persistence in the environment and growing links to human health risks. While laboratory-based testing remains the gold standard for PFAS detection, its high cost, technical complexity, and limited accessibility pose significant challenges, particularly for large-scale monitoring and regional communities. Addressing this gap, Henry Bellette, PhD candidate at La Trobe University, is part of a research team developing a portable, biosensor-based screening tool designed to enable rapid, affordable, and on-site detection of PFAS. In this interview with NUFFOODS Spectrum, Bellette discusses the motivation behind the technology, its potential role alongside conventional testing, implications for food and water safety, and the key steps required to translate the biosensor from a research prototype into a widely deployed handheld device.

What gap in current PFAS detection and monitoring did your team aim to address with this portable biosensor, particularly regarding food and water safety?

Our sensor, as well as biosensors more generally, aim to address affordability, portability, and ease-of-use of sample testing. The current mainstream methods of PFAS testing involve expensive equipment that is limited to a laboratory setting, can only be used by highly trained professionals, and incurs a high cost. This is not compatible with large scale screening, especially in regional and remote areas.

How does the biosensor’s “yes or no” screening approach compare with conventional laboratory-based testing in terms of reliability, sensitivity, and practical decision-making?

We don’t expect a simple “yes/no” screening tool to replace lab-based analytical methods. Instead, it could be used alongside them, helping direct when and where more expensive testing is needed.

For example, for the cost of three lab tests, you might complete 50 screening tests across a much larger area. If any sites are flagged as potentially PFAS-affected, you could then run targeted lab analysis only at those locations.

A useful health analogy is COVID-19 rapid antigen tests (RATs). They enabled fast, affordable, on-the-spot screening. Where a RAT indicated a possible case, follow-up laboratory PCR testing could confirm the result.

Given the widespread use of PFAS in food packaging and processing, how could this technology support preventive monitoring across the food and beverage supply chain?

We haven’t tested our PFAS sensor on food and beverage samples, as our work so far has focused primarily on environmental monitoring.

That said, if we developed suitable sample preparation and testing protocols for these products, many of the same biosensor benefits could apply, including more affordable, mobile, and easy-to-use screening for the food and beverage industry.

As PFOA is highly regulated globally, how adaptable is your sensing platform to detecting other PFAS compounds as regulations evolve?

PFAS regulation is extremely fast evolving. However, we believe that regulation will become more ubiquitous globally, and the need for affordable, portable, and easy-to-use screening will grow.

Although we developed the sensor for PFOA, we believe the sensor will respond to other PFAS, but with differing sensitivities. PFOS is one PFAS that is also commonly regulated, and that we believe has a good chance of working with our sensing platform. However, future research will need to investigate if, and to what degree, the sensor responds to PFOS and other regulated PFAS.

What advantages does on-site, rapid screening offer for regional and remote communities with limited access to specialised testing facilities?

Regional and remote communities are much less likely to have the lab facilities needed for traditional PFAS analysis, and they’re often a long way from the labs that do exist. This increases both the cost and the time it takes to get results and make decisions.

Affordable, rapid on-site screening can reduce these delays and costs. Because testing happens locally, it can be done more often and across more locations. That helps communities respond quickly and builds local capability that would otherwise be too expensive or impractical.

What are the key technical, regulatory, or commercial milestones required to transition this biosensor from a research prototype into a widely deployed handheld device?

To move our PFAS sensor from the lab to real-world use, there are three key milestones. Technically, the device must show reliable, ultra-sensitive detection of PFOA and related PFAS in complex samples like drinking water, ground water, and possibly human blood with consistent performance across large numbers of tests. From a regulatory perspective, it needs validation against accredited laboratory methods and approval for environmental and, eventually, clinical use. Commercially, the sensor must be manufacturable at scale, affordable, and robust enough for routine use by non-experts, such as water utilities, regulators, or healthcare providers. Achieving all three is what will turn our promising PFAS sensor into a practical handheld tool.

Shraddha Warde

shraddha.warde@mmactiv.com

Technology

Sidel introduces SWING Evo Pasteuriser, Redefines Efficiency through Intelligent Design

Mar 06, 2026 | Company News

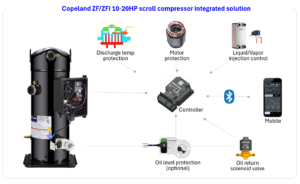

Copeland Launches ZF/ZFI 10-20HP Scroll Compressors

Mar 05, 2026 | Company News

Food Testing

NSF and Circle H Collaborate to Enable Global Certification Access

Mar 04, 2026 | Company News

Australian Medical Bodies Push for Compulsory Health Star Labelling

Feb 24, 2026 | Australia

Tim Hortons Singapore Secures Majlis Ugama Islam Singapura Halal Certification Ahead of Ramadan

Feb 23, 2026 | Company News

More Popular

Nutrition Education Drives Adoption of Seaweed and Mussels among Bangladesh Coastal Communities

Mar 06, 2026 | Food Security

Sidel introduces SWING Evo Pasteuriser, Redefines Efficiency through Intelligent Design

Mar 06, 2026 | Company News