Friday, 27 February 2026

LanzaTech to produce nutritional protein

Company plans to access $1 trillion alternative protein market by commercialising primary production of nutrient-rich protein through LanzaTech’s proprietary gas fermentation process LanzaTech Global, the carbon recycling company transforming waste…

Company plans to access $1 trillion alternative protein market by commercialising primary production of nutrient-rich protein through LanzaTech’s proprietary gas fermentation process

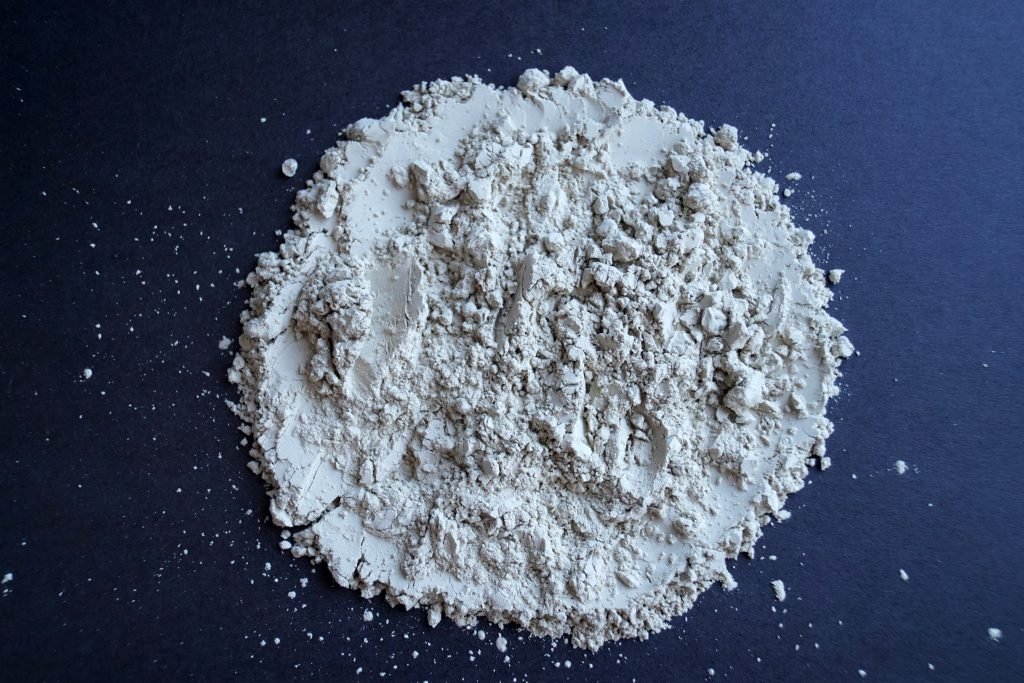

LanzaTech Global, the carbon recycling company transforming waste carbon into sustainable fuels, chemicals, materials, and protein, announced its plans to expand its biorefining platform capabilities to include operations that produce LanzaTech Nutritional Protein (LNP) as the primary product. LNP is a microbial protein that is a nutrient-rich alternative to plant and animal-based proteins. By using a new microbe in its proprietary gas fermentation process, LanzaTech’s biorefining platform can produce a cost-competitive protein solution that supports a resilient food supply chain. LNP production can address food security issues and be produced anywhere in the world, independent of weather extremes. Notably, the production of LNP uses a fraction of the land and water resources that traditional protein sources require.

With the development of LNP production facilities, LanzaTech will gain access to the large and growing alternative protein markets, diversifying its customer base, expanding its sources of revenue, and optimising the value creation driven by its existing, proven platform.

“Building on the expertise of our commercially operating core gas fermentation process, LNP represents a natural expansion of our business,” said Dr Jennifer Holmgren, CEO of LanzaTech. “By coupling a new microbial production strain with our existing bioreactor technology, and our years of operating experience, we have developed a path to mass produce protein from CO2. We’ve operated a pilot facility for two years to prepare for commercialization. In the process, we’ve partnered with leading brands and food testing organizations for rigorous analysis and prototyping of nutrition applications. We have now progressed into the engineering design phase for a 0.5 to 1.5 tonne per day facility, expected to be operational in 2026. We have developed a roadmap to commercial-scale production in 2028.”

Technology

Ingredion Thailand Achieves 100% Sustainably Sourced Cassava

Feb 27, 2026 | Company News

Deakin University and Bellarine Foods Partner to Develop Sustainable Marine-Derived Proteins

Feb 26, 2026 | Australia

Royal Unveils Refreshed Jute Bag Design for 20lb Authentic Basmati

Feb 25, 2026 | Company News

Food Testing

Australian Medical Bodies Push for Compulsory Health Star Labelling

Feb 24, 2026 | Australia

Tim Hortons Singapore Secures Majlis Ugama Islam Singapura Halal Certification Ahead of Ramadan

Feb 23, 2026 | Company News

More Popular

Fagron Acquires Pharmavit Europe for €68Mn to Expand Nutraceutical Portfolio

Feb 27, 2026 | Company News

Arla Foods Invests EUR 300Mn in New Cheese Dairy in Sweden

Feb 27, 2026 | Company News

Beyond Meat Broadens Portfolio Beyond Protein with Sparkling Plant-Based Drink Line

Feb 27, 2026 | Beverages