Saturday, 7 March 2026

Meat-Tech 3D achieves significant milestone

The plan is to develop an industrial process, with integrated 3D digital printing technology, for growing and producing cuts of beef without harming animals Israel based Meat-Tech 3D Ltd. has announced…

The plan is to develop an industrial process, with integrated 3D digital printing technology, for growing and producing cuts of beef without harming animals

Israel based Meat-Tech 3D Ltd. has announced that it has achieved a significant milestone: it has successfully printed a uniform, thin, slaughter-free meat tissue produced from stem cells.

Meat-Tech’s successful experiment is a technological breakthrough that significantly increases the feasibility of Meat-Tech’s technologies.

Meat-Tech’s most important experiment to date transpired as part of the company’s multi-year work plan. The plan is to develop an industrial process, with integrated 3D digital printing technology, for growing and producing cuts of beef without harming animals.

Designated as “Project Carpaccio”, due to its similarity to the thinly-sliced meat delicacy, Meat-Tech applied its proprietary 3D printer for tissue construction, followed by a cell-growth process. Meat-Tech’s scientists succeeded in printing several cell types, which coalesced into a single fat and muscle tissue grown in Meat-Tech’s laboratory.

This feat has brought about the coalescence of a living tissue composed of several different bovine cells. The experimental results were analyzed by a professional examiner and corroborated by the company’s audit committee.

This milestone demonstrates three significant process capabilities attained by Meat-Tech:

– Successful sorting of stem cells into fat and muscle cells, allowing the synthesis of muscle fibers and fat tissue;

– Formulation and production of bio-inks designed to print fat and muscle cells to ultimately form tissues; and

– The formation of printed tissue containing coalesced fat and muscle cells.

Technology

Sidel introduces SWING Evo Pasteuriser, Redefines Efficiency through Intelligent Design

Mar 06, 2026 | Company News

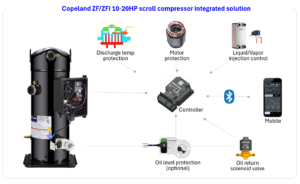

Copeland Launches ZF/ZFI 10-20HP Scroll Compressors

Mar 05, 2026 | Company News

Food Testing

NSF and Circle H Collaborate to Enable Global Certification Access

Mar 04, 2026 | Company News

Australian Medical Bodies Push for Compulsory Health Star Labelling

Feb 24, 2026 | Australia

Tim Hortons Singapore Secures Majlis Ugama Islam Singapura Halal Certification Ahead of Ramadan

Feb 23, 2026 | Company News

More Popular

Nutrition Education Drives Adoption of Seaweed and Mussels among Bangladesh Coastal Communities

Mar 06, 2026 | Food Security

Sidel introduces SWING Evo Pasteuriser, Redefines Efficiency through Intelligent Design

Mar 06, 2026 | Company News