Thursday, 5 March 2026

BGG expands manufacturing facilities in China

The 100 per cent glass-tube photobioreactor microalgae platform in Yunnan Province BGG is expanding and enhancing its astaxanthin manufacturing facilities in China to boost production efficiency, quality, innovation, and sustainability.…

The 100 per cent glass-tube photobioreactor microalgae platform in Yunnan Province

BGG is expanding and enhancing its astaxanthin manufacturing facilities in China to boost production efficiency, quality, innovation, and sustainability.

The 100 per cent glass-tube photobioreactor microalgae platform in Yunnan Province – the largest of its kind in the world – will now incorporate the entire value chain. As a result, farming, extraction, drying, packaging, and R&D will all be brought together within a 20km footprint.

BGG is also strengthening its resources by opening a new, cutting-edge research laboratory and more than doubling the size of its on-site R&D team. The team will focus on microalgae innovation and further advances in ingredient quality. They will also work closely with regional and global research institutes on tropical plants and fungi in the local biome.

The concentration of capabilities will support greater operational efficiency and productivity through faster tech transfer times and closer collaboration between operations and R&D. Reducing the value chain from 2,000km to 20km will also support cost efficiency and reductions to the carbon footprint.

BGG’s investment in its flagship plant is being marked with an inauguration day at the facility on June 20, with industry partners and representatives from the Chinese government in attendance. It follows on from a major expansion in 2023-2024, which more than doubled BGG’s production capacity and cemented its position as the world’s largest astaxanthin producer.

Technology

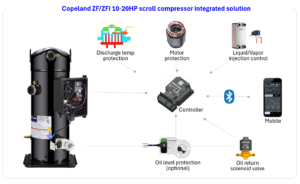

Copeland Launches ZF/ZFI 10-20HP Scroll Compressors

Mar 05, 2026 | Company News

WA Scientists Discover New Deep-Sea Crustacean Stocks with Strong Commercial Potential

Mar 05, 2026 | Australia

Food Testing

NSF and Circle H Collaborate to Enable Global Certification Access

Mar 04, 2026 | Company News

Australian Medical Bodies Push for Compulsory Health Star Labelling

Feb 24, 2026 | Australia

Tim Hortons Singapore Secures Majlis Ugama Islam Singapura Halal Certification Ahead of Ramadan

Feb 23, 2026 | Company News

More Popular

Copeland Launches ZF/ZFI 10-20HP Scroll Compressors

Mar 05, 2026 | Company News

Singapore Expands Support for Local Farms to Strengthen Food Security

Mar 05, 2026 | Food Security