Thursday, 5 March 2026

Unilever’s AI-driven cleaning pilot saves €100,000, cuts utility use by 10%

This initiative is part of the broader 100+ Accelerator programme, a global platform designed to fast-track sustainable solutions through partnerships between leading consumer goods companies and start-ups In a major…

This initiative is part of the broader 100+ Accelerator programme, a global platform designed to fast-track sustainable solutions through partnerships between leading consumer goods companies and start-ups

In a major boost for supply chain sustainability, Unilever has successfully piloted a smart liquid cleaning system at its nutrition factory in Poznan, Poland, in collaboration with emerging start-up H2Ok Innovations. This initiative is part of the broader 100+ Accelerator programme, a global platform designed to fast-track sustainable solutions through partnerships between leading consumer goods companies and start-ups.

The new AI and Internet of Things (IoT)-enabled system has significantly enhanced efficiency by reducing machine cleaning times by 20 per cent, cutting utility consumption by 10 per cent, and delivering annual savings of €100,000. The breakthrough highlights the potential of smart technologies in transforming FMCG manufacturing processes and sets a benchmark for future innovation across the industry.

Launched by Anheuser-Busch InBev and co-sponsored by Unilever, Coca-Cola, Colgate-Palmolive, and Danone, the 100+ Accelerator provides an innovation testbed where start-ups tackle real-world challenges defined by the programme’s corporate partners. Each year, the initiative invites start-ups to propose scalable solutions to shared sustainability problems, particularly within supply chain management and R&D.

“Open innovation can be tricky when you’re sitting across the table from your competitors,” says Charlotte Ward, Global Head of Unilever’s Climate and Nature Fund. “We work to ensure the challenges set are in areas that are relevant to the entire consumer goods industry.”

She adds, “To solve the world’s greatest challenges, collaboration is essential. 100+ Accelerator provides a mechanism for like-minded businesses to learn from one another and to scale solutions quickly, which benefits their respective businesses and generates transformative impact.”

The successful deployment of H2Ok Innovations’ system demonstrates how cross-industry partnerships and open innovation can accelerate progress toward a more sustainable and efficient future for global manufacturing.

Technology

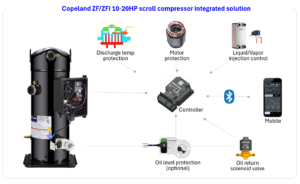

Copeland Launches ZF/ZFI 10-20HP Scroll Compressors

Mar 05, 2026 | Company News

WA Scientists Discover New Deep-Sea Crustacean Stocks with Strong Commercial Potential

Mar 05, 2026 | Australia

Food Testing

NSF and Circle H Collaborate to Enable Global Certification Access

Mar 04, 2026 | Company News

Australian Medical Bodies Push for Compulsory Health Star Labelling

Feb 24, 2026 | Australia

Tim Hortons Singapore Secures Majlis Ugama Islam Singapura Halal Certification Ahead of Ramadan

Feb 23, 2026 | Company News

More Popular

Copeland Launches ZF/ZFI 10-20HP Scroll Compressors

Mar 05, 2026 | Company News

Singapore Expands Support for Local Farms to Strengthen Food Security

Mar 05, 2026 | Food Security