Tuesday, 3 March 2026

Neogen launches Petrifilm automated feeder to improve food safety testing

Petrifilm end-to-end solution reduces hands-on enumeration time from 4 hours to 1 minute Neogen Corporation, an innovative leader in food safety solutions, is helping high-volume food safety testing laboratories implement…

Petrifilm end-to-end solution reduces hands-on enumeration time from 4 hours to 1 minute

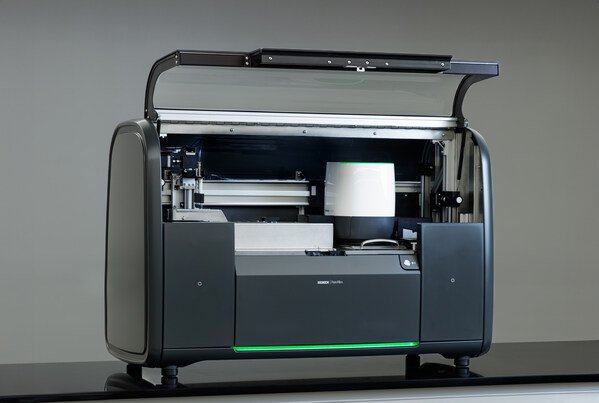

Neogen Corporation, an innovative leader in food safety solutions, is helping high-volume food safety testing laboratories implement a more efficient way to process quality indicator tests. The launch of Neogen’s Petrifilm Automated Feeder will provide industry-leading indicator testing processing capabilities that build on 40 years of innovation across Petrifilm’s portfolio.

The Petrifilm Automated Feeder works with existing Petrifilm Plate Reader Advanced equipment to help labs efficiently process microbial tests and meet food safety standards. It delivers consistent colony counting and improves lab productivity by automatically feeding and enumerating up to 300 Petrifilm Plates in 33 minutes while integrating with existing lab workflows and systems.

The system is specifically designed for high-volume food safety testing labs processing more than 100,000 quality indicator tests per year. With Neogen’s automated system, technicians no longer need to manually load plates into the reader or count and record initial results. Eliminating these tasks adds capacity for these labs, allowing more time for data analysis.

“This introduction is the latest step in the history of Petrifilm innovation to help make labs more efficient and productive,” said John Adent, President and CEO of Neogen. “By reducing the time burden on technician staff, Neogen is helping labs evolve and efficiently meet growing demands and deliver safe, high-quality food while meeting testing requirements for food and ingredients. Neogen is excited to be at the forefront of investments in innovation, microbiology, and food safety to evolve the modern lab.”

Technology

IPC Report Flags Rapidly Deteriorating Food Security across Somalia

Mar 02, 2026 | Africa

University of Florida Develops Vitamin A–Rich Tomato to Tackle Global Deficiency

Mar 02, 2026 | Food

Inside the World’s First AI Centre of Excellence for Chocolate and Cocoa

Mar 02, 2026 | Interaction

Food Testing

Australian Medical Bodies Push for Compulsory Health Star Labelling

Feb 24, 2026 | Australia

Tim Hortons Singapore Secures Majlis Ugama Islam Singapura Halal Certification Ahead of Ramadan

Feb 23, 2026 | Company News

More Popular

Wildbrine Launches Industry-First Fermented Bean Salad

Mar 02, 2026 | Company News

IPC Report Flags Rapidly Deteriorating Food Security across Somalia

Mar 02, 2026 | Africa

University of Florida Develops Vitamin A–Rich Tomato to Tackle Global Deficiency

Mar 02, 2026 | Food